1. Static Mixers and Heat Exchangers for the Confectionery Industry

Static mixers and Heat Exchangers are a simple and cost effective method of blending and controlling products reliably, their benefits include:

- Eliminating the need for tanks, agitators, moving parts and direct power

- Highly efficient heat transfer with advanced connection technology

- No moving parts making the component virtually maintenance free

- Easy installation

- Consistent product quality

- Mixing C02 into fruit juices.

- Pasteurisation of concentrated fruit

- Mixing Milk with acids

- Pasteurisation and cooling of sauces

- Diluting concentrates and mixing flavourings

- Cooling of Chocolate Spreads / Peanut butter

- Rework of margarine based products

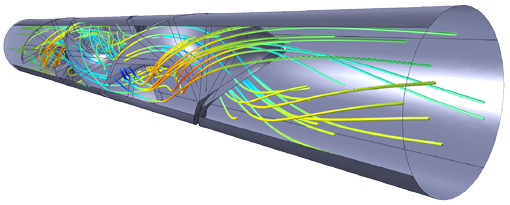

Static Mixers are normally engineered based on homogeneity, where mixing should be efficient. Technical homogenous is 96% homogeneity. If the number of elements is reduced mixing efficiency decreases. The amount of elements required depends on several parameters, like velocity and viscosity. To obtain maximal flexibility element chains of 1,2,4 and 8 mixing elements were supplied. With these 4 items, combinations can be made of 1-15 mixing elements, providing sufficient flexibility for testing.

All our Mixers and Heat Exchangers are made to meet the specific process requirements of each application, our team of engineers will be more than happy to help with any of your queries.

Our most popular static mixers are built from stock components in AISI 316L or PVC and are available for rapid dispatch enabling a speedy turnaround.

2. Inline batch processing and mixing

Benefits

- Custom design

- Flexible set-up

- Cost effective

- Short clean time

A lost market for a production company is often the small custom made batches because the existing production lines are most cost effective for continuous large runs and cleaning time is significant. Profit margins for small custom made batches on the other side are normally very attractive. Is a static mixer the solution?

Design:

Custom made batches are characterised because they contain a basic product that is produced in large quantities, and specific additives to customise. Examples are specific tastes, colours or chemical resistance additives.

In principle the inline batch process unit consists of the following parts; main component tank, additive tanks, dosing pumps, transport pump, static mixer and a control panel. This is a fully flexible set up and will be adjusted for your application and industry, and can be used as a batch or as a continuous inline processing system.

Solution:

The heart of the unit is the static mixer that has been designed to achieve a homogeneous mixture within the operation range where flow rates and viscosities can change.

The brain is the control panel where all functions are displayed and controlled including all switches, indicating lights, interfaces and the PLC. Pumps are selected based on the application; demands in the food are different form the chemical industry.

Other components like the tanks, level-and flow sensors are also selected based on the application-demands. Fully jacketed tanks with an own independent hot water system and easy CIP models are optional.

This inline batch-processing unit makes it possible for companies to enter a new market that has never been possible before.

For further information please contact our Sales Department

3. Mixing off shear sensitive products

Benefits

- Specific design

- Controlled process

- Better quality

- Low shear forces

Some products can withstand high shear forces others are very sensitive for it. Main characteristics of the product like viscosity or appearance can change when shear forces are too high. Could a static mixer be used to mix a shear sensitive product just before the filling machine?

Design:

The enquiry came from one of the largest European companies that produces polish product for domestic use. The company faced all kind of viscosity problems in the filling machine due to the high shear forces in the current agitator. The purpose of the mixer is to very gently blend a base polish with perfume. The perfume is injected at the entrance of the mixer. Because the mixer must be installed in an existing machine, available space is limited.

Solution:

To obtain very low shear forces, a low velocity is required. As a result the flow pattern is laminar so 16 mixing elements are required. To fit the mixer in the available space, it has been formed into a U-shape. This also enables dismantling of the mixer-elements from one side. The perfume is being introduced into the main flow by a removable centreline injection.

The mixer is constructed in such a way it can be completely dismantled by its tri-clamp connections.

The results were so successful that the second line has also been updated recently.

For further information please contact our Sales Department

English

English French

French German

German Dutch

Dutch Russian

Russian Polish

Polish